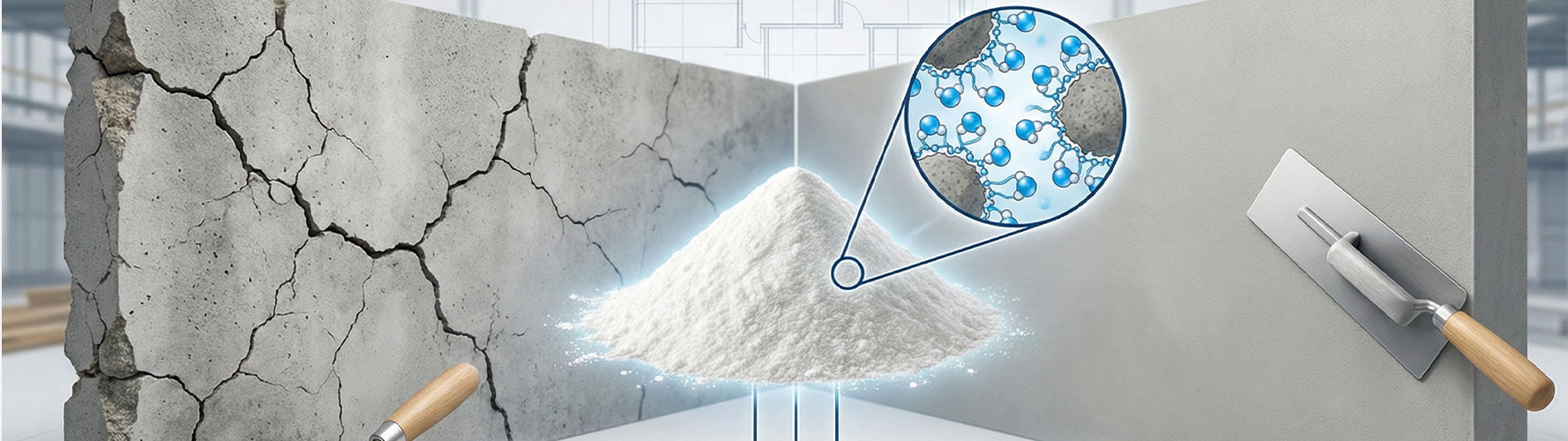

羟丙基甲基纤维素(HPMC):解决混凝土开裂和强度问题

2026-01-05 19:52In the global construction industry, the demand for high-performance building materials is surging. Two major challenges—concrete cracking and insufficient structural strength—often lead to project delays and safety concerns.

As a premier manufacturer, we provide high-purity Hydroxypropyl Methyl Cellulose (HPMC), a critical additive specifically engineered to address these pain points and ensure the longevity of modern infrastructure.

1. Enhanced Crack Resistance through Moisture Regulation

Cracks in cement-based materials are primarily caused by dddhhhplastic shrinkagedddhhh when water evaporates too quickly from the surface.

The Solution: Hydroxypropyl Methyl Cellulose creates a microscopic film within the mortar, significantly slowing down the evaporation process.

Outcome: This superior Crack Resistance ensures that the surface remains intact and smooth, even in harsh, dry, or windy environments.

2. Optimizing Cement Hydration for Maximum Hardness

The strength of any concrete structure depends on the chemical reaction between cement and water, known as Cement Hydration.

The Problem: Without enough water, this reaction ($2(3CaO \cdot SiO_2) + 6H_2O \rightarrow 3CaO \cdot 2SiO_2 \cdot 3H_2O + 3Ca(OH)_2$) stops prematurely, leading to weak, brittle walls.

The HPMC Advantage: By retaining water within the mix, our Hydroxypropyl Methyl Cellulose ensures that every cement particle undergoes full hydration, maximizing the compressive and flexural strength of the final product.

3. Superior Bond Strength for Multi-Substrate Application

High-rise buildings often use diverse materials like AAC blocks, red bricks, and concrete. Ensuring a firm dddhhhgripdddhhh between these layers is vital.

Adhesion Power: Our construction-grade Hydroxypropyl Methyl Cellulose acts as a thickener and lubricant, dramatically increasing the Bond Strength.

Result: It prevents the common issue of dddhhhhollow soundsdddhhh or tiles falling off, providing a secure and durable bond that lasts for decades.

4. Industry-Leading Water Retention Rate

For professional contractors, the Water Retention Rate is the gold standard for evaluating HPMC quality.

Technical Performance: Our premium Hydroxypropyl Methyl Cellulose offers a water retention rate of $\ge 90\%$.

Efficiency: This high efficiency extends the Open Time of mortar, allowing workers to cover larger areas without the material drying out prematurely, thus reducing labor costs and material waste.

5. Effective Shrinkage Control and Dimensional Stability

Post-construction shrinkage is a leading cause of internal stress and structural fissures.

Mechanism: By regulating the internal humidity of the mortar, Hydroxypropyl Methyl Cellulose provides precise Shrinkage Control.

Benefit: It minimizes volumetric changes during the hardening phase, ensuring that self-leveling floors and wall plasters remain perfectly flat and stable.

Technical Specification Overview

| Application | Recommended Grade | Viscosity Range (mPa.s) | Key Feature |

| Wall Putty | Construction Grade | 40,000 - 100,000 | Smooth Finish & Anti-cracking |

| Tile Adhesive | High Adhesion Grade | 100,000 - 150,000 | High Bond Strength & Open Time |

| Self-leveling | Low Viscosity Grade | 400 - 1,000 | Excellent Flow & Shrinkage Control |

Conclusion

Choosing the right Hydroxypropyl Methyl Cellulose is not just about buying an additive; it is about guaranteeing the quality of your construction project. Our products are exported globally, helping builders overcome cracking and strength issues through advanced chemical engineering.